OPTION

Line up

Temperature Sensor

Real-time temperature monitoring instantly reflects measurement results.

*Applicable to 2400, 2600 Series only

Automatic Probe Cleaning

Automatically removes foreign substances such as flux, improving measurement stability.

*Applicable to 2400, 2600 Series only

Full Spectrum Sensor

Evolved LED color testing, enabling inspection of UV and IR.

*Applicable to 2400, 2600 Series only

Lateral illumination

Creates shadows, making contours clearer.

*Applicable to 2400, 2600 Series only

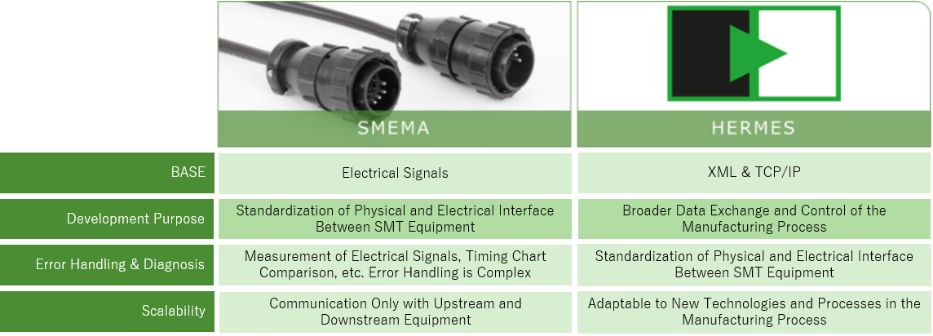

HERMES Standard Compliance

In addition to conventional SMEMA standard communication, it now supports communication via the HERMES standard (IPC-HERMES-9852).

*Applicable to 2400, 2600 Series only

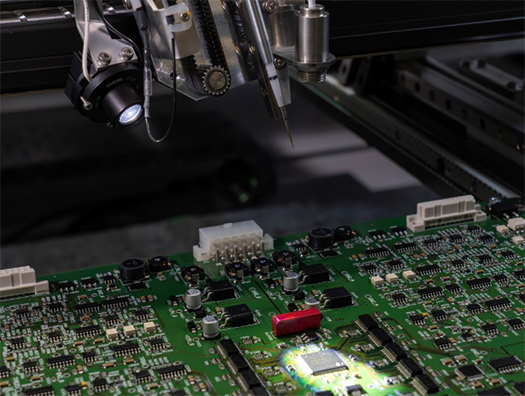

IC Open Test System

Electrical detection of IC lead solder failure in BGA, QFP, SOJ, etc.

LED Color Test System

Automatic and numerical determination of mounted LED test

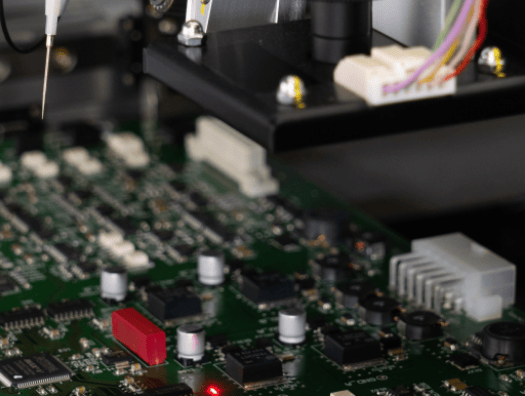

Laser Displacement Measurement System

Combined test of in-circuit test + laser displacement measurement

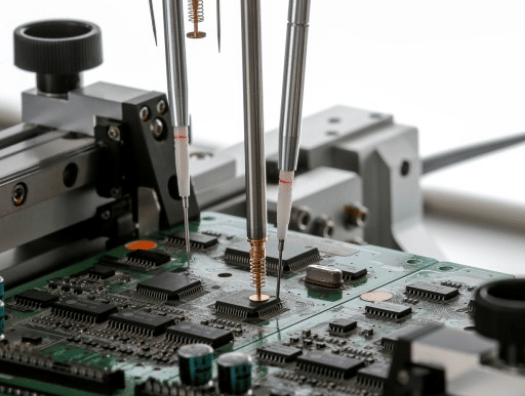

Vertical Probe

Expansion of defect detection area

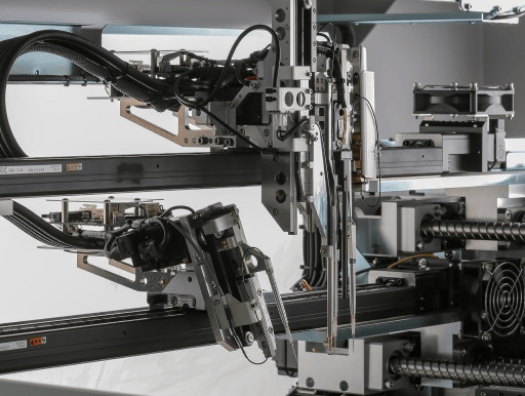

Inline Model

Conveyor transfer is ideal for ICT test of mass-production circuit boards

Combination with JTAG boundary scan test

Combination test of ICT and BST

Multi-Probe System

Connection to external equipment via multi-probe on a dedicated jig

MES system communication via OPC UA

Data exchange across equipment types, OS, manufacturers

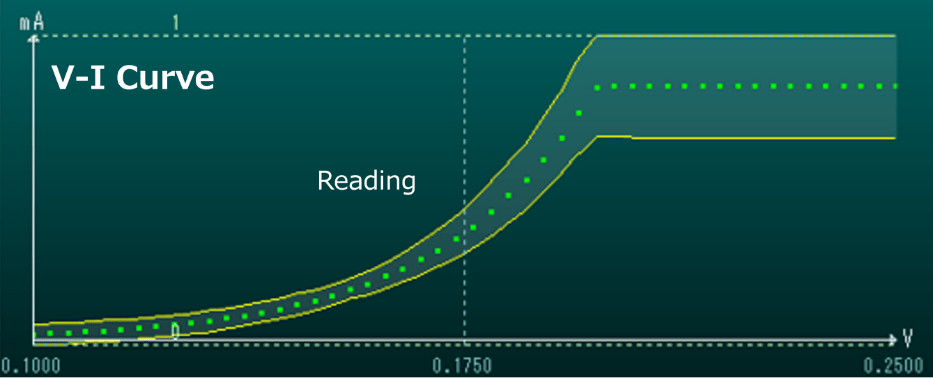

Temperature Sensor

Real-time temperature monitoring instantly reflects measurement results.

The newly developed temperature sensor measures V-I curves to detect semiconductor failures and misassembled components that conventional in-circuit testing cannot. It also offers temperature compensation and non-contact measurement to prevent temperature drift, further improving test coverage.

*Applicable to 2400, 2600 Series only

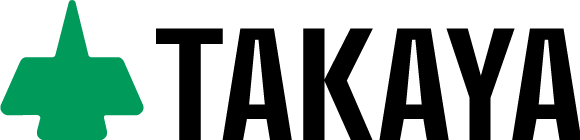

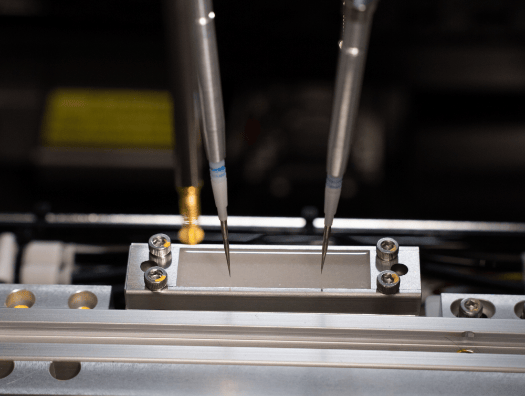

Automatic Probe Cleaning

Automatically removes foreign substances such as flux, improving measurement stability.

The system includes a probe cleaner that automatically removes flux and dust from the flying probe tips, with adjustable cleaning interval. This reduces false judgments and ensures stable, reliable inspections.

*Applicable to 2400, 2600 Series only

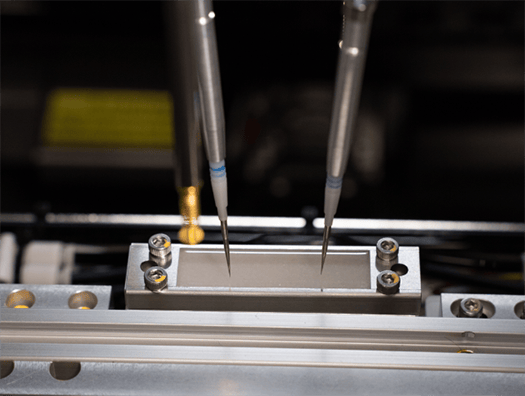

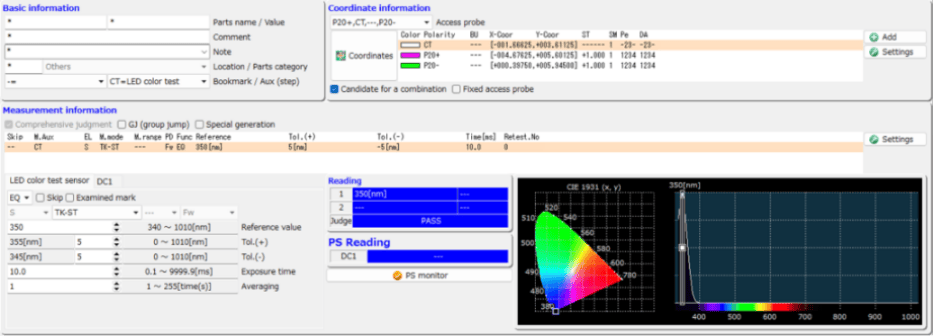

Full Spectrum Sensor

Evolved LED color testing, enabling inspection of UV and IR.

With spectral measurement using a spectrometer that measures wavelengths from 340nm to 1010nm, it supports LED inspections in the UV and IR ranges that could not be tested with conventional LED color tests.

*Exclusive option for APT-2400F / APT-2600FD (mutually exclusive with LED color test system)

*Applicable to 2400, 2600 Series only

Lateral illumination

Creates shadows, making contours clearer.

By illuminating the object from an angled direction, shadows are created by surface irregularities, making it easier to capture the contours of the object.

Effective for reading laser-engraved 1D and 2D codes.

Lateral illumination can be mounted on axis of 1, 4, 5, and 6.

*Applicable to 2400, 2600 Series only

HERMES Standard Compliance

In addition to conventional SMEMA standard communication, it now supports communication via the HERMES standard (IPC-HERMES-9852).

The HERMES standard is an open standard for transmitting production data between equipment within an electronic assembly line, offering a wider range of functions than the SMEMA standard. It allows for the exchange of detailed product information, production process data, equipment operating status, quality control data, and more complex information.

It enables more advanced data exchange and control of the manufacturing process, including integration with production management systems and quality management systems.

*Exclusive option for APT-2400F / APT-2600FD

*Applicable to 2400, 2600 Series only

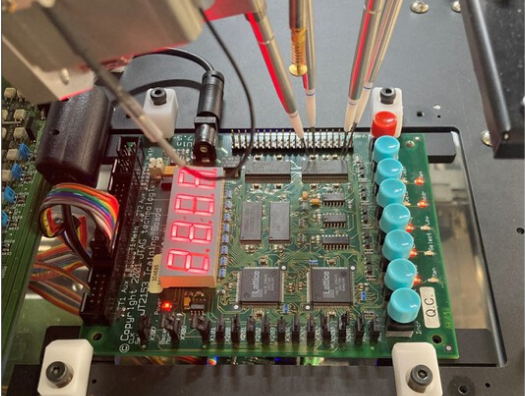

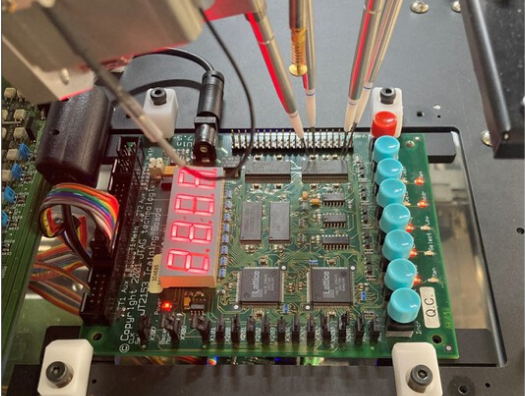

IC Open Test System

Electrical detection of IC lead solder failure in BGA, QFP, SOJ, etc.

The sensor probe is placed over the IC package and reads the signals emitted from inside the IC to make numerical determinations.

This allows lead solder failure in BGA, QFP, SOJ, etc. to be electrically detected without damaging the IC unit.

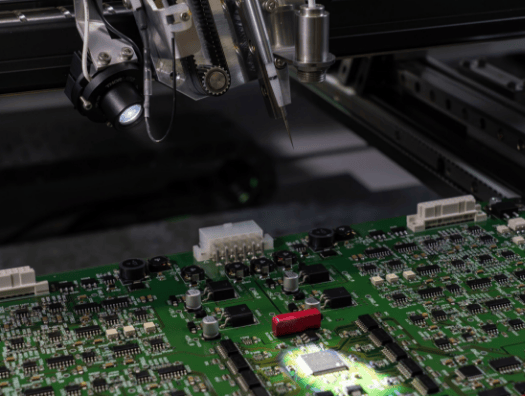

LED Color Test System

Automatic and numerical determination of mounted LED test

The LEDs on the circuit board are illuminated and the emitted color is detected using a dedicated color sensor. It quantifies the hue, saturation, and brightness of the emitted color, normally difficult to distinguish visually, enabling stable test with clear criteria. There is no need to prepare a dedicated jig.

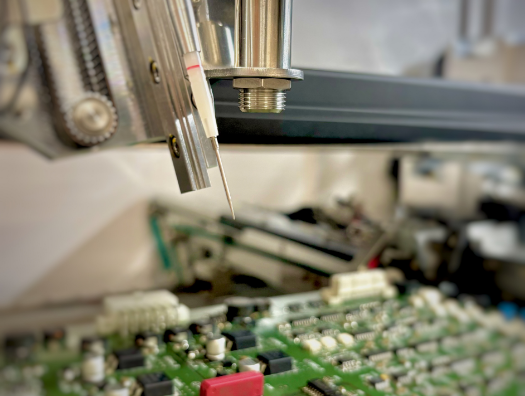

Laser Displacement Measurement System

Combined test of in-circuit test + laser displacement measurement

Measures the height between the circuit board surface and the component upper surface in a non-contact manner by optical measurement using laser light, and reliably detects mounting defects such as component float, which cannot be detected by in-circuit testing.

It also has a function of detecting the amount of circuit board warpage and automatically correcting the probe contact position to prevent contact errors.

APT-1400F series: Optional

APT-1600FD series: Standard

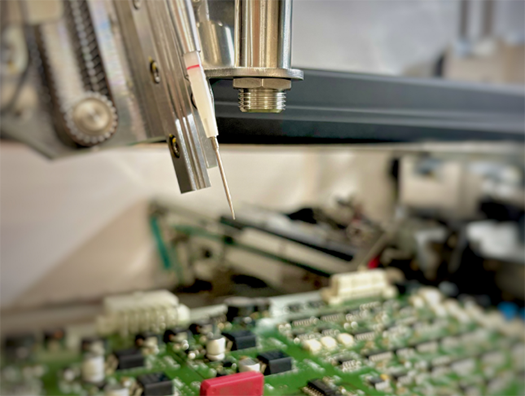

Vertical Probe

Expansion of defect detection area

Two vertical probes are added to the standard four tilted probes to accurately contact points in the gaps between components and points that have been previously inaccessible, such as vias, through-holes, and upward connectors, thus enhancing defect detection ability.

Several types of probes with different tip shapes are available so that the optimal contact method can be selected according to the shape of the test target.

In addition, the dual Z-axis option that automatically switches between two different types of vertical probes according to the test program eliminates the need for manual probe replacement, allowing for more efficient test.

Inline Model

Conveyor transfer is ideal for ICT test of mass-production circuit boards

Supports inline test that incorporates a flying probe tester into the production line for efficient mass production.

Fully automated test by connecting with the SMT line and with the loader/unloader/flipper contributing to reducing the burden on operators and saving labor cost.

When used with a 3D-AOI (Visual inspection machine), defects that cannot be detected by image inspection itself, such as micro-bridges, can be reliably detected electrically. This eliminates false information, improving test capability and increases speed.

Combination with JTAG boundary scan test

Combination test of ICT and BST

In-circuit testing using a flying probe tester excels at testing the electrical characteristics of mounted electronic components in analog circuits. However, components that cannot be contacted are difficult to test electrically, and dofunctional tests of digital circuits. In such cases, the boundary scan test can perform in a short time for interconnection test between LSI pins and on-board programming to FPGAs, etc., but it can only test digital circuits around ICs that conform to the boundary scan standard and a dedicated jig may be required for the connection.

Instead of using a jig for connecting between the 4-5 scanning pins and a device required for the boundary scan test, Takaya flying probe tester have an own technology to testwithout using any additional jigs. This allows you to perform the boundary scan test by making the flying probe function as a virtual boundary scan cell, even if ICs complied with BST or non-complied ICs and connectors are mixed.

This technology makes test more efficient than ever before, allowing simultaneous test of both digital and analog circuits with a flying probe tester.

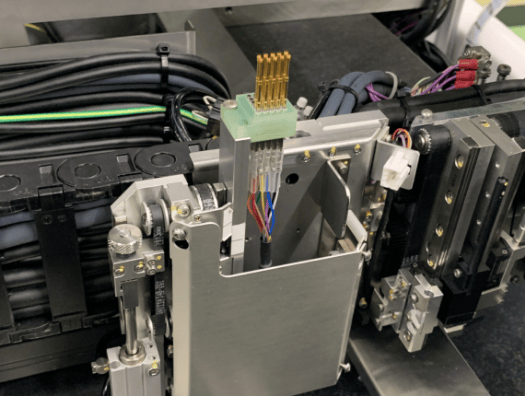

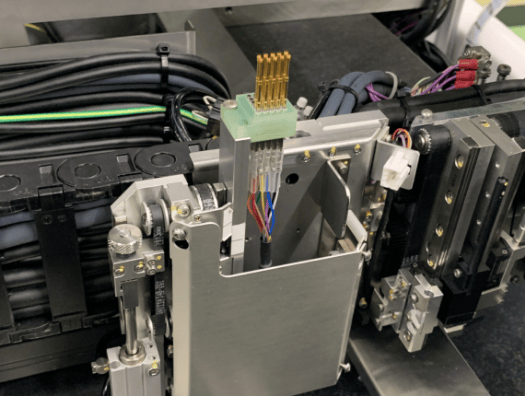

Multi-Probe System

Connection to external equipment via multi-probe on a dedicated jig

This is an option to install a dedicated jig lifting mechanism on the bottom side of the APT-1600FD series.

It allows special test that connect to external equipment such as BST (JTAG boundary scan test), and the In System Programing/log reading of FPGAs and other ICs to be performed in parallel with in-circuit test.

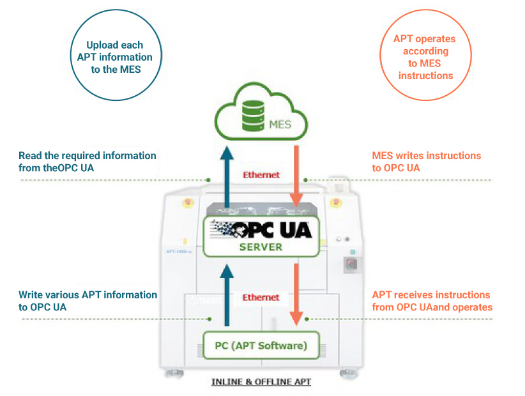

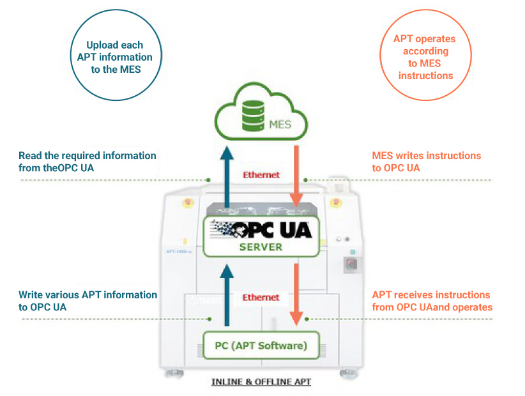

MES system communication via OPC UA

Data exchange across equipment types, OS, manufacturers

OPC UA (OPC Unified Architecture) is an open international standard established for secure and reliable data exchange in industries.

After the OPC foundation announced it in 2008, it was internationally standardized under IEC62541. It is recommended as a standard communication for Industry 4.0 and is spreading around the world.

Takaya offers an option to install an OPC UA server to the APT series of flying probe testers. We are working to promote the industrial IoT standard to bridge factory automation equipment and IT.

- Stand-alone type / Inline type

- Single sided

APT-2400F

Entry model with four probes for single-sided test

2400F supports the testing of high-density mounted boards, boasting industry-leading probing accuracy, and achieves highly reliable electrical tests. Capable of ultra-high-speed tests at a speed of 0.02 seconds/step.

- Stand-alone type / Inline type

- Single sided

- Large size

APT-2400F-SL

Four-probe single-sided test for large printed circuit boards

2400FD-SL supports the testing of large-sized mounted boards such as power supply boards and probe cards. Capable of testing boards up to 985 x 610mm. Achieves both highly accurate positioning and high-speed test.

- Stand-alone type / Inline type

- Double sided

APT-2600FD

Flagship model with six probes for double-sided test

2600FD is equipped with four probes on the top side and two probes on the bottom side of the board. Each probe moves freely at high speed, achieving world-class test speed through simultaneous dual-side contact.

- Stand-alone type / Inline type

- Double sided

- Large size

APT-2600FD-SL

Six-probe flagship model for double-sided test of large circuit boards

2600FD-SL maintains the basic performance of the APT-2600FD while increasing size, realizing an expanded test range and reduced time.

- Stand-alone type / Inline type

- Single sided

APT-1400F

Entry model with four probes for single-sided test

APT-1400F is a standard model which is capable of testing all types of assembled printed circuit boards.

- Stand-alone type / Inline type

- Single sided

- Large size

APT-1400F-SL

Four-probe single-sided test for large printed circuit boards

APT-1400F-SL is for the test of large assembled printed circuit boards.

- Stand-alone type / Inline type

- Double sided

APT-1600FD

Flagship model with six probes for double-sided test

Four probes are equipped above the top surface and two under the bottom surface of the circuit board.

- Stand-alone type / Inline type

- Double sided

- Large size

APT-1600FD-SL

Six-probe flagship model for double-sided test of large circuit boards

APT-1600FD-SL can test a large, long circuit boards of up to 985×610 mm without losing the performance.

For detail information,

please contact our certified partners in your region.