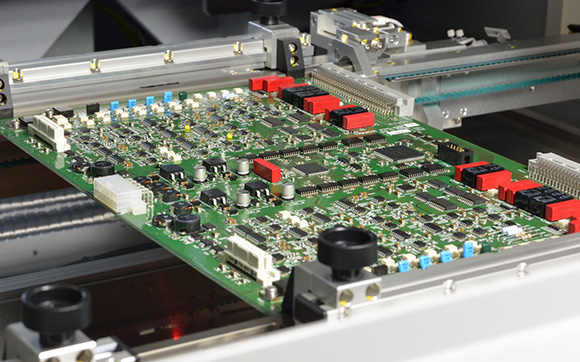

Flying Probe Tester

The TAKAYA APT series comprises test systems for the detection of production defects on assembled printed circuit boards using probes moving very fast independently of each other so that a conventional bed of nail adapter is no longer required. As early as 1987, TAKAYA developed the concept of the Flying Probe Tester that combines the advantages of advanced electrical test methods and high-precision mechanics. Since that time, TAKAYA has been leading in the field of flying probe technology.The research and development capacities concentrate on the fast launch of product innovations on the market to be able to react immediately to the rapidly changing technical requirements and needs of the customers in the many different areas of the electronics industry.

The APT-1400F and the test systems of the APT-9000 series represent the latest generation of flying probe systems. The systems combine the knowledge and decades of experience in the areas of actuation and positioning of the probes and the measurement technology. The APT-1400/9000 systems, in addition to the maximum positioning accuracy and test speed, are also distinguished by outstanding test coverage. Not only extensive electrical tests are used here but also many optical tests supplement the test result.

REDUCTION OF THE TEST COSTS

Fixtures are generally used during the In Circuit test for testing assembled printed circuit boards. The manufacture of these fixtures usually takes one if not several weeks. As well as the long manufacturing time, the high costs also play a significant role. Particularly in production with high type diversity, fixtures can quickly develop into cost drivers for the manufacture, storage and maintenance.

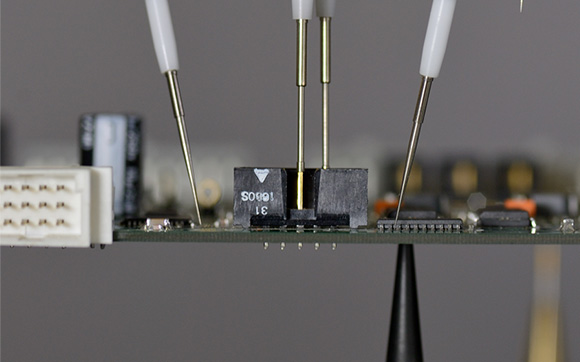

PRECISE AND GENTLE CONTACTING

Contact points with a size of 60 µm can be reached and contacted with precision using the four or six flying probes. The "Design for Test" effort is thus reduced and testing of complex SMD boards is also possible without test points. Using soft touch control of the Z-axes, it is possible to put the probes on the contact surfaces gently and carefully without significantly influencing the test speed in doing so.

COMPREHENSIVE TESTS

As well as high precision measuring equipment for analogue and digital components, 4-quadrant power supplies, sine and rectangular wave generators, frequency counters, LED sensors etc. are available. With this wide range of test options, a large variety of different components can be measured quickly and precisely.

SIMPLE AND USER-FRIENDLY SOFTWARE

Intelligent and customer-oriented tools enable user-friendly handling of the systems from the program creation to the fault analysis. Versatile auxiliary tools for the programming support the automatic determination of reference values, guard points and measurement conditions. Numerous troubleshooting and fault analysis programs for fast editing of the test programs are also available. The test programs can be created in the "Teach In" process or also from the CAD data. TAKAYA Merlin Pro software that supports over 40 different CAD systems is available for this.

OPTICAL TESTING INCLUDED

The APT systems have a powerful recognition system for reliable and precise automatic optical testing. The optical system detects missing, offset or polarity-reversed components and thus increases the test coverage for the components that cannot be tested using an electrical test. The camera also records 1D and 2D barcodes and includes these in the test reports. Measurement and assignment of the results without gaps are thus always guaranteed.

IC OPEN CHECKER

The IC Open test system option enables the testing of IC contacts in bus structures. The measurements of the internal protective diodes in the IC are supported by special sensor technology using which defective solder joints on QFPs and SOPs and on most BGAs can be discovered.

EXTERNAL COMMUNICATION

The test systems of the APT series are equipped with interfaces for the communication with external measuring and testing systems. Whether boundary scan, frequency measurements, In-System programming, external function tests etc., connections to external testing systems are easily possible thanks to the open platform. External, programmable DC current and voltage supplies can also be integrated in the test process. "Plug and Play" solutions are available here.

QUALITY AND RELIABILITY

One of the most important components of the flying probe systems is the measuring equipment, but the mechanical design of the system is just as decisive. Do not make any compromises here!

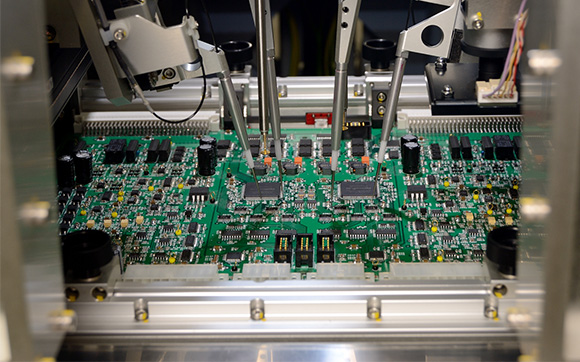

IN-LINE APPLICATIONS

All APT systems are of course also available as In-Line variant. Equipped with a transport system with automatic width adjustment, the flying probe testers can be used for completely automated operation in a production line or in magazine to magazine operation.